A leak in your sprinkler system can be a great cause for concern, potentially reducing the effectiveness of your fire protection system. It’s like a safety shield developing cracks. At Western States Fire Protection, we prioritize your safety and strive to equip you with the essential knowledge to maintain a reliable fire protection system. This article will explore the common causes of leaks in fire protection systems, steps to take upon discovering a leak, and strategies to prevent future leaks.

Deconstructing the Causes

Fire protection systems serve as the frontline defense in protecting lives and property. Therefore, understanding why your fire protection system is leaking is crucial in promptly addressing the issue and preserving its long-term effectiveness.

Corrosion is a major cause of leaks in sprinkler systems. Moisture and environmental factors can corrode pipes over time, leading to small holes or cracks. Older systems or those in harsh environments are especially vulnerable. The main types of corrosion include:

- Oxygen Corrosion – For years, misinformation about oxygen corrosion in steel sprinkler piping has spread within the fire sprinkler industry. It’s now widely recognized that oxygen is the leading cause of corrosion problems in sprinkler piping. Oxygen, making up about 21% of the air in the system, dissolves in water that contacts the pipes, making it available to react with the metal. Oxygen’s interaction with steel pipe is influenced by three key physical attributes:

- Oxygen has low solubility in water and only participates in corrosion after dissolving, as it requires water to react with steel.

- Once dissolved, the oxygen and water mix reacts quickly with the steel, causing rust, similar to how rust forms on vehicle brake rotors after rain.

- Dissolved oxygen has poor mobility in stagnant water, so corrosion primarily occurs near trapped water in dry systems and trapped air in wet systems, although it can happen elsewhere.

- MIC – Microbiologically Influenced Corrosion happens when microorganisms interact with a material’s surface, making it prone to corrosion through different mechanisms. There are three subtypes of MICs that can lead to corrosion:

- Slime Formation – Corrosion Under Deposits: Slime or bacterial buildup can create layers on the metal surface, trapping moisture and causing corrosion underneath these deposits.

- Acid Production – Acidic Attack and Corrosion: The production of acids leads to an increase in acidity (H+ ions), which can aggressively attack and damage the metal, resulting in pitting or small holes.

- Sulfide Production – Enhanced Corrosion: The creation of sulfide ions disrupts the normal flow of the corrosion process, speeding up corrosion and leading to pitting in the metal surface.

Manufacturing defects in fire sprinkler systems can also cause a sprinkler head leaking. Despite stringent quality controls, defects can occur during production. Faulty seals, improper welding, or weak connections can all contribute to a leak in the sprinkler system. Mechanical damage to the sprinkler heads, pipes, or other system components can also result in a leak in the sprinkler system. Accidental impacts, improper handling during maintenance or installations, or even natural disasters can inflict such damages.

Immediate attention to any leaks is crucial to maintaining the system’s functionality. Regular inspections, maintenance, and repairs by certified professionals can help identify and rectify any issues before they escalate. This process can be handled easily by us as we offer all these services in-house and even have the capability to maintain your system, identify any issues, and repair what is needed.

Discovering a Fire Sprinkler Leak: The Next Steps

If you find a sprinkler head is leaking, taking immediate action is essential to minimize damage and ensure the system functions correctly. Here are some steps to follow:

- Stop the water flow:Upon discovering a leak, your first step should be to stop the water flow to prevent further damage. Locate the main water supply valve for your fire protection system and turn it off to contain the leak and minimize water damage.

- Document the leakage:Before any repairs or clean-up begin, thoroughly document the leak. Take pictures from various angles to demonstrate the extent of the damage. Also, write down details such as the date, time, and location of the leak, and any observations you have regarding its cause. This documentation can be invaluable when filing an insurance claim.

- Seek professional help:The best way to assess corrosion in a fire sprinkler system is through pipe sample analysis. ECS offers this service by examining corroded pipe sections to determine the cause of metal loss and estimate the remaining service life.

Then, Western States Fire Protection removes a damaged pipe section, or a previously removed section can be submitted for analysis. The inspection reveals the type of corrosion, remaining wall thickness, and pit depths. The analysis includes a report with the likely cause of corrosion, tailored recommendations for repair and prevention, and sample images.

Pipe Analysis Features

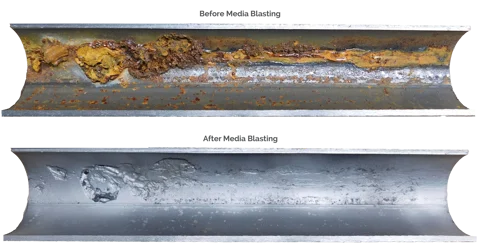

- The pipe sample is cleaned and sectioned for a detailed visual inspection.

- The analysis identifies the type of corrosion, remaining wall thickness, and calculates the corrosion rate (mils per year).

- A thorough report is provided, including photographs taken before and after media blasting.

Pipe Analysis Benefits

- This is the most cost-effective method for analyzing corrosion in fire sprinkler systems.

- It offers concrete data on the root cause and extent of corrosion.

- The analysis is essential for making informed pipe replacement decisions based on wall thickness measurements.

- It also assesses the risk of blockages caused by buildup.

Understanding the extent of corrosion through pipe analysis is essential for making informed decisions about your fire sprinkler system. By identifying the root cause of corrosion and evaluating the severity of the damage, you can address potential issues before they lead to system failures. Acting on this information helps prevent costly repairs and ensures the longevity of your fire protection system.

Remember, promptly addressing a leak in your fire protection system is crucial for maintaining its ability to safeguard your property and ensure the safety of occupants. By following these steps and seeking professional help, you can minimize the damage caused by the leak and restore your fire protection system’s functionality.

Avoiding Future Leaks in Your Sprinkler System

To maintain your fire protection system’s optimal performance and lifespan, it’s crucial to take proactive steps to prevent leaks. Regular inspections and maintenance can help detect potential issues before they become significant problems. Implementing corrosion prevention measures can greatly reduce the risk of a sprinkler head leaking. One such method is introducing nitrogen into the system to displace oxygen, which helps prevent rust and corrosion within the pipes and fittings.

For someone with a dry or pre-action fire sprinkler system, proactivity can look like:

- Regular Pipe Inspections – Schedule routine inspections to check for early signs of corrosion or damage. Catching issues early allows for timely repairs and prevents larger problems.

- Monitor Air Leaks – Ensure that the system is airtight to avoid the introduction of oxygen-rich air. Regularly inspect for leaks and fix them promptly to maintain system integrity.

- Water Drainage Maintenance – Ensure that any water entering the system is properly drained, as trapped water can accelerate corrosion. Regularly check and clear drainage points.

- Corrosion Monitoring Devices – Install corrosion monitoring devices within your system to detect and measure corrosion rates. This helps in assessing the effectiveness of preventive measures.

- Perform Pipe Sample Analysis – Periodically remove and analyze pipe sections to determine corrosion levels and remaining service life. This provides concrete data to inform maintenance decisions.

- Stay Compliant with NFPA Standards – Ensure that your system and maintenance practices are in line with the National Fire Protection Association (NFPA) standards to maintain safety and performance.

Specifically for dry pipe systems you can also implement Dry Pipe Nitrogen Inerting (DPNI) which uses the DPNI process with a nitrogen generator to eliminate oxygen from the piping, preventing corrosion before it starts. This can significantly extend the lifespan of your system. By following these proactive measures, you can significantly reduce the risk of corrosion and ensure your sprinkler system remains reliable and effective.

Make the Call

When it comes to ensuring the longevity and optimal performance of your sprinkler system, you can trust our team of experts. We offer comprehensive installation services to ensure that your sprinkler system is set with care, and our regular maintenance program includes thorough inspections and necessary repairs to keep your system running smoothly. We also specialize in efficient corrosion management to prevent any damage to your sprinkler system caused by rust or other corrosive elements by using pipe scans from ECS to better understand systems issues and lifespans. With our expertise and attention to detail, you can finally put an end to that pesky fire sprinkler leak. Contact us today to get this service set up for your property!